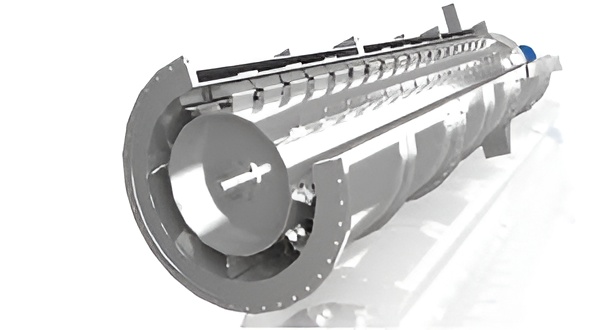

ATFD based plant (Agitated Thin Film dryer)

At Radox Engineering, Jaipur, we provide state-of-the-art Agitated Thin Film Dryer (ATFD) Based Zero Liquid Discharge (ZLD) Systems , designed to offer efficient and eco-friendly solutions for wastewater treatment. Our ATFD-based ZLD systems are particularly effective for industries where high-quality solid waste management and complete water recovery are essential. The system ensures zero discharge of liquid waste by transforming wastewater into reusable water and safe solid waste, making it a sustainable solution for various industries.

-

Specifications of Agitated Thin Film Dryer (ATFD) Based Zero Liquid Discharge (ZLD) System:-

-

Core Process – Agitated Thin Film Dryer (ATFD):

Thin Film Evaporation: The ATFD process involves a thin layer of liquid being evaporated on a heated surface under high agitation. This increases the surface area and facilitates faster evaporation of water, leaving behind concentrated waste.

Continuous Operation: The ATFD system operates continuously, ensuring that large volumes of wastewater can be processed without interruptions. This is ideal for industries with high effluent generation rates.

-

Zero Liquid Discharge (ZLD) Process:

Water Recovery: The evaporated water from the ATFD process is condensed and recovered as clean, reusable water. This water can be reused in the industrial processes or even be sent for further purification if necessary.

Solid Waste Treatment: The residual concentrate, typically composed of salts, chemicals, and other non-evaporated solids, is handled and processed to form solid waste. This waste can be safely disposed of or used for other applications, such as fertilizers.

Zero Discharge: With a focus on sustainability, the system ensures that no liquid waste is discharged into the environment, thus achieving a zero liquid discharge status. -

Scalability and Integration:

Modular System*: The system can be scaled up or down depending on the wastewater volume, providing flexibility for different types of industrial operations.

Seamless Integration: The ATFD-based ZLD system can be integrated with existing water treatment facilities or installed as a standalone solution to handle wastewater treatment and achieve zero liquid discharge.

Environmental Compliance:

Zero Liquid Discharge: The ATFD system adheres to strict environmental regulations by eliminating any liquid discharge, contributing to sustainability and reducing the environmental impact of wastewater disposal.

Solid Waste Management: The remaining concentrated solids are treated and processed for safe disposal or recycling, minimizing waste and further reducing environmental harm.

The Agitated Thin Film Dryer (ATFD) Based Zero Liquid Discharge (ZLD) System from Radox Engineering provides a high-efficiency, energy-saving solution for industries seeking to achieve zero liquid discharge while recovering reusable water and safely managing solid waste. With its robust design, automation, and focus on sustainability, this system offers an effective and eco-friendly approach to wastewater treatment.